- Why are companies importing special-shaped component plug-in machines

- Brand advantages of Tungson multifunctional fully automatic special-shaped component plug-in machine

- The second generation "OCM-II Multi functional Alien Component Plug in Machine" has been successfully launched. Start simultaneously

- Who can perceive the opportunities and make the right choices in the crisis of the transformation of the manufacturing industry?

- Experiential training enhances the company's competitiveness

- Tungson Automation held a fire drill

Address: 5th Floor, Building B1, Songhu Zhigu Research Center, No. 6 Minfu Road, Liaobu Town, Dongguan City, Guangdong Province

Tel:0769-85389385

Fax:0769-85411416

E-mail:sales@tungson.hk

Page views:

Order Hotline:0769-85389385

OCM-IIL Multi functional Irregular Component Plug in Machine OCM-II Data Download

In the 80s, there was an AI revolution in the electronics industry

The 90's electronics industry has once again witnessed a SMT mounting revolution

Today, the birth of Tungson OCM (Multi functional Irregular Component Plug in Machine)

Leading the new generation revolution in the electronics industry

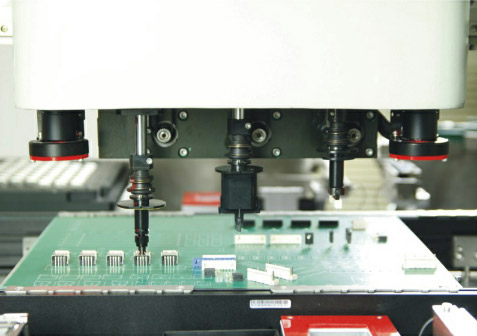

| 1. Modular design, convenient and time-saving wire replacement, and improved efficiency 2. Accurate insertion and installation of components to ensure quality and reduce costs 3. Fundamentals of SMT machine software, human-machine intelligent operation interface 4. Preset various component information and flexibly call it from the component library 5. Embedded design of feeder, does not occupy external space 6. Data management to avoid human errors 7. Equipped with pressure sensing function, automatically identifying pins to improve the quality of actual insertion 8. Automatic identification of component polarity function to avoid component reverse insertion 9. IC pin forming function, saving secondary investment 10. Industry 4.0 mode with powerful software management and remote monitoring. |  |

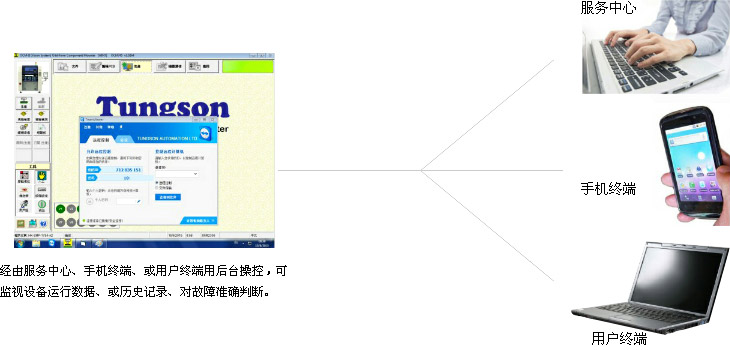

Remote operation and monitoring

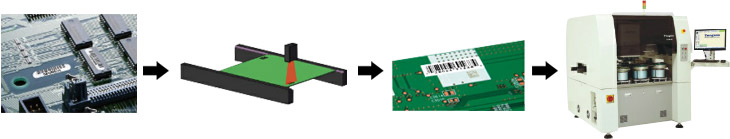

Barcode automatic recognition system

Automatically check the PCB barcode when entering the board, identify the identity and eliminate the wrong board entering.

Hardware and software

|  |

| Stable and reliable-Original imported screws, Panasonic servo motors and other main components. |  |

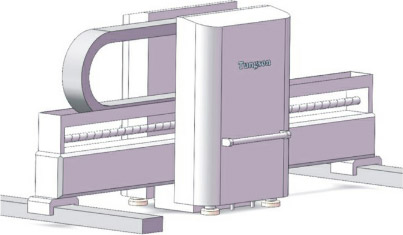

| modularization-The feeding device of Tungson OCM-II is easy, simple, and fast to replace, ◆ Replacing a set of feeder devices only takes 2 minutes ◆ Quick pull connector design, the nozzle or pneumatic finger can be replaced in just 20 seconds ◆ The feeder is equipped with a communication connection needle holder, which is plug and play ◆ The time for changing lines is 80% less than that of the same type of mechanical equipment ◆ Can be switched to bulk, strip, tube, and tray feeding stations ◆ Built in DC power supply system to prevent safety accidents caused by improper operation by personnel. |  |

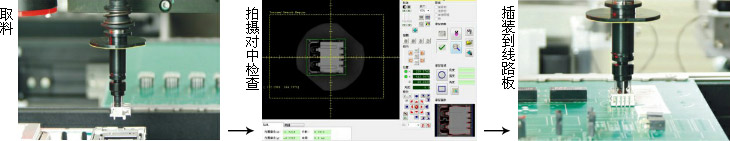

Central system-High precision pin alignment recognition and component shape analysis function, fully realizing precision insertion of irregular components.

| Software- ◆ The CHP system can monitor various production conditions such as production cycle and efficiency in real time< br/> ◆ Automatic development of MT-6D system, integrated numerical control of 12 vibration source amplitude parameters< br/> ◆ The reference points and coordinates for PCB assembly are easy to copy, greatly reducing programming time< br/> ◆ Equipped with PCB bad board recognition function to avoid wasting component materials< br/> ◆ Offline programming (* 1) can be used to preset production line feeding configuration and insertion mode< br/> ◆ PPVC program simulation function, for checking the distribution and movement routes of plug-in devices. |  |

Material retrieval tool

Suction-The suction nozzle is easy to fold and install, suitable for picking up various shaped components, especially when the machine is used for multiple purposes. The suction nozzle can be replaced quickly and the conversion efficiency is high.

Pneumatic finger-The pneumatic finger developed by Tungson is easy to disassemble and assemble, suitable for grasping various shaped components, with strong compatibility, stability and reliability.

Insertable materials

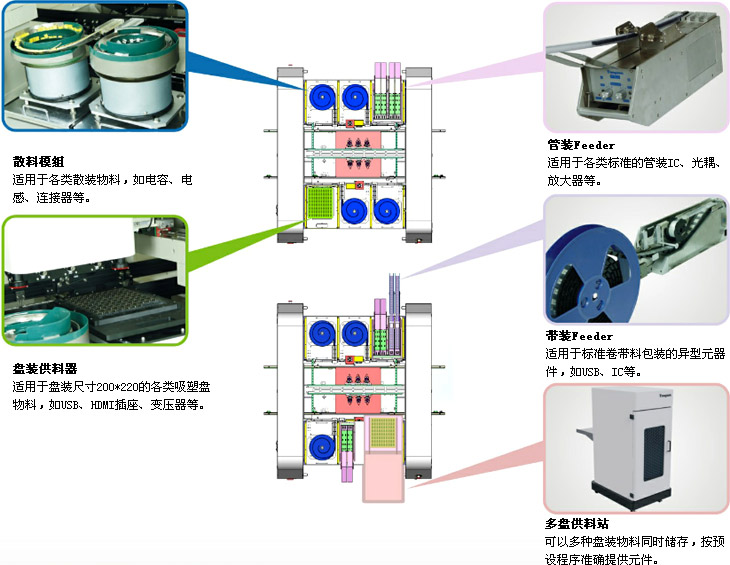

Multiple optional feeding systems

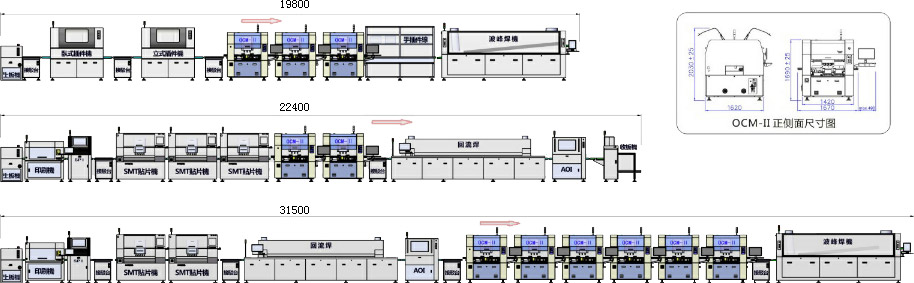

Production line combination reference

| project | parameter |

| host | |

| Ground clearance height of the transmission track | 930±30mm |

| Equipment external dimensions | L1670*W1620*H1690mm(*4) |

| Net weight of the host | Approx. 1000kg |

| Fastest speed for mounting/inserting | 2400cph |

| PCB Conveyor System | |

| PCB board size that can be loaded | L50*W50-L490*W420mm |

| Fixed edge position | front end |

| PCB transfer direction | L-> R or r-> L |

| PCB transmission thickness | 0.8-3.0 |

| Transmission track width adjustment method | Digital automatic width adjustment Digital Control |

| Maximum load of conveyor belt and track | 3.0Kg |

| The upper/lower components can be adjusted by height | Up 45/Down 15 |

| Plug in platform | |

| Repetitive accuracy of X/Y/Z axis | ±0.01mm |

| X/Y-axis drive mode | servo motor |

| Repetitive accuracy of R axis | ≤±0.1° |

| Drive mode for each plug-in head (Z and R axes) | Independent servo motor |

| Replacement method of suction nozzle/gas finger | Quick release connector |

| Positive/Negative Pressure Switching | Component library editing |

| Pressure sensing function | Level optional |

| Number of load-bearing feeding stations | 3+3 (or above) |

| Various types of feeding stations can be configured | Bulk, strip, tube, tray, and multi tray feeding stations (* z) |

| electrical system | |

| SMEMA online signal interface | European 14 pin SMEMA socket |

| Power requirements | Two sets of single-phase 220V -240V 20A |

| software | |

| operating system | Win7 (licensed software) |

| Main program software | Human computer intelligent software |

| Can store programming data for PCB boards | ≥200 |

| Editable component classes in the component library | Max.999 |

| Archive import format | CAD/TXT |

| Other software functions | Offline Programming (* 1) Barcode Scanning& Automation System; identification(*3) |

| Teaching demonstration and video system | |

| CCD video camera | Top two, bottom two |

| Component/Pin Alignment | Camera discrimination below |

| Copy the coordinates of PCB assembly | 0& deg;/ 90& deg;/ 180& deg;/ 270& deg; copy |

| Can check the Bad mark mark on the puzzle board | Check the camera on top |

| safety equipment | |

| Safety door equipment | Induction switch, stop immediately upon opening the door |

| Pressure failure alarm | Positive pressure or vacuum |

| CE safety standards | prepare |

| Other | |

| Dimensions of insertable components (L * W * Hmm) | 3 * 3 * 5-40 * 40 * 45 (including pin length) |

| Pressure gas input requirements | 4-7 kg/cubic meter |

Note: * 1=optional items * 2=ongoing projects * 3=conditional limitations * 4=excluding signal tower lights, monitors, keyboard and mouse trays

| Safety precautions | |

| •Before use, please read the user manual carefully before using it correctly. | •In order to safely use the products listed in the catalog, please carefully confirm the user manual and warning signs attached to the equipment before performing the correct operation, whether the product is running or stopped. |

Chinese

Chinese

13829276376

13829276376